Concept

Cleanroom redefined

Forget about steel or concrete.

Think fabric to separate clean air from contaminated air!

Whether you need a certified cleanroom or an machine enclosure - with sphairlab you get exactly what you need.

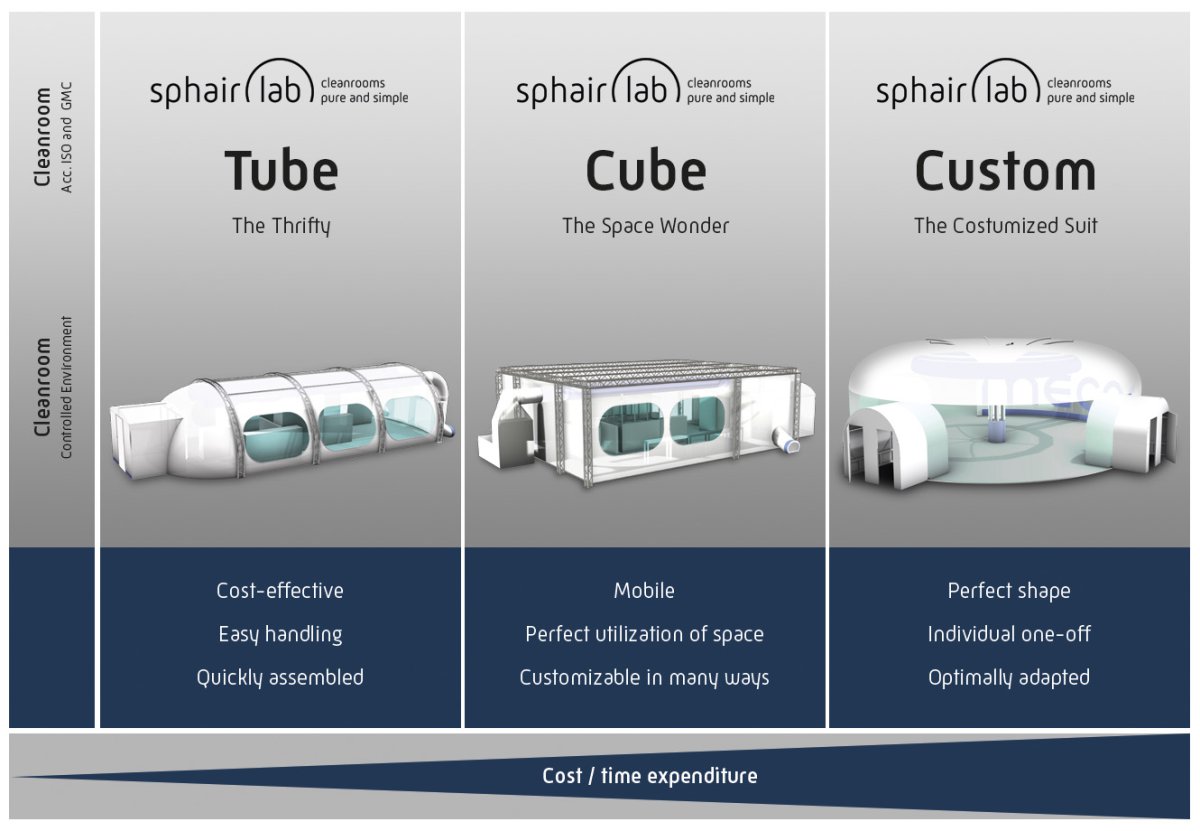

How does it work?

It's quite simple: The air inside the sphairlab is the "building material" - the fabric shell is kept in place due to overpressure. The ventilation follows the recirculation principle and takes in the air outside the cleanroom, filters it according to the cleanliness class and distributes it evenly throughout the cleanroom. The air exits through the flaps in the wall and is drawn in again by the recirculation system.

The best thing: You save money! Because textile fabric is way cheaper than steel and concrete. Even better: Your cleanroom becomes mobile! Because you can quickly set up, dismantle and transport your sphairlab.

And best of all: it looks fantastic!

sphairlab – The movie

Please call us on +49-163-2518059 or write to us at

Browse through the sphairlab brochure - just click on it

Clean-room

Focused on the essentials

Focused on the essentials

We cut the high-quality, certified fabric to your individual requirements and wishes. This opens up unimagined design possibilities for the cover in every conceivable shape. A reliable ventilator ensures constant overpressure and keeps it permanently in shape.

The functionally equipped cleanroom airlock is also given such a cover. Inside, the long-life LED lighting supplied puts workstations in the right light. Simple, pure and sufficient, right? The strengths of the sphairlab really come into their own with temporary and project-based use: simply let the air out at the end! What remains is the lightweight shell with a tiny transport and storage volume.

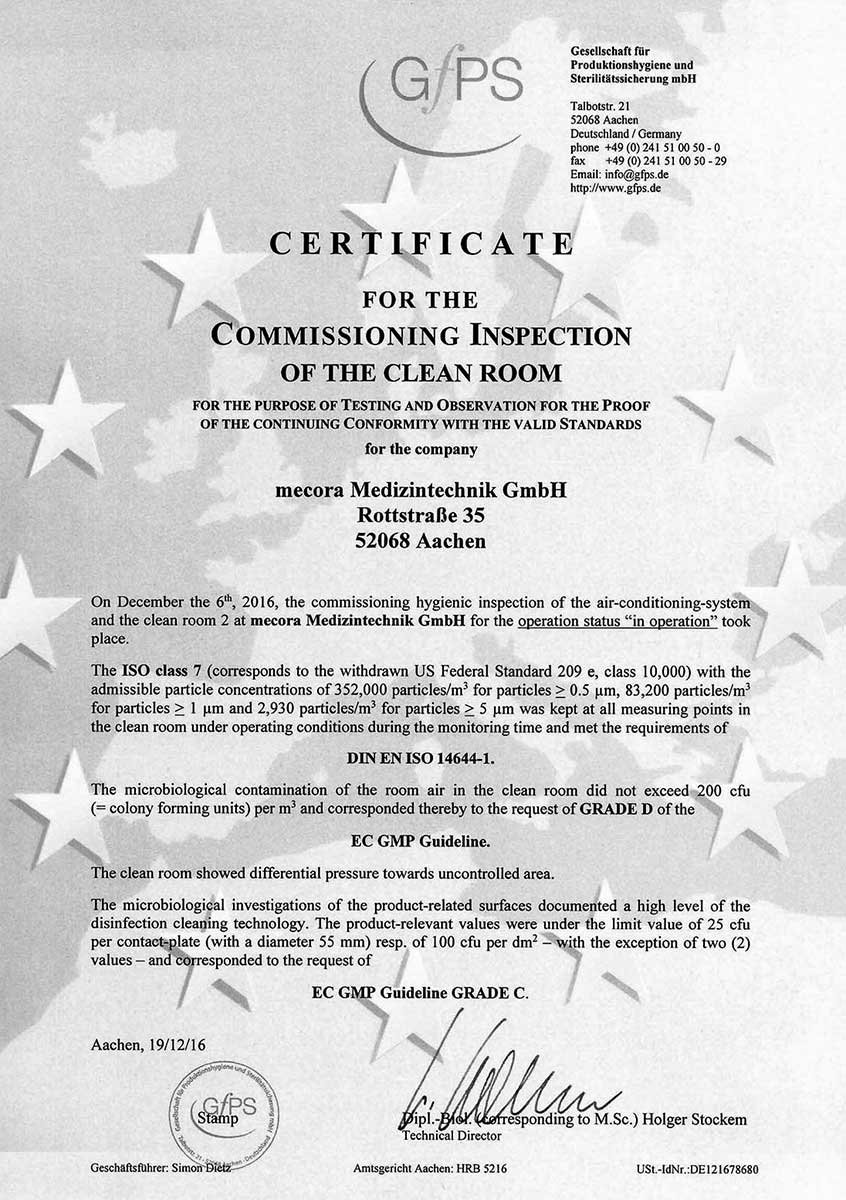

Certified

Despite its simplicity, we naturally supply sphairlab with documentation appropriate to the room class.

Please call us on +49-163-2518059 or write to us at

Enclosure

Would you like a little less?

You don't need a cleanroom with its strict guidelines for your purposes? Then simply opt for a sphairlab as an enclosure!

The covers for the room and airlock are of the same quality as the cleanroom. But: For the lower requirements for cleanliness in an enclosure in accordance with VDA 19, a less expensive blower and a simpler airlock are sufficient, as it only has to maintain the pressure gradient. And above all: the documentation for an enclosure is less complex. The overall price is therefore even lower than it already is!

So why buy more than you need?

Please call us on +49-163-2518059 or write to us at

References

The pure application

Customised and attractive solutions for our customers: This is what we are committed to, quickly and competently.

Simply give us a call!

Why Dr. Fritz Faulhaber GmbH & Co. KG bought a sphairlab? Sphairlab offers a mobile cleanroom solution that was realized within 10 weeks, from order to commissioning. The room was designed entirely according to our requirements and space conditions due to the individual production - true to the motto "performance in the smallest space".

Thanks to this flexible solution, we were able to expand our cleanroom capacity quickly and cost-effectively.

Markus Bessey

Process development

"A sphairlab can be easily integrated into different rooms. If necessary, the room can even be dismantled and rebuilt elsewhere. This feature, together with the good price-performance ratio and the attractive appearance, made it easy for us to decide for a sphairlab."

Dr.-Ing. Dipl.-Wirt.-Ing. Ralf Borchardt

Chief Technology Officer

enmodes GmbH, Aachen

"The sphairlab impressed me with its high flexibility and the textile, transparent design. Especially in the academic world, where there is no continuous production, the sphairlab is ideally suited to periodic, project-dependent use thanks to its simple installation and deinstallation.

This saves considerable operating costs and enables flexible use of space."

Univ.-Prof. Dr. med. Stefan Jockenhövel

NRW Priority Professorship BioTex - Biohybrid & Medical Textiles

RWTH Aachen University, Institute for Applied Medical Engineering

"Our new cleanroom impresses with a completely different look. In terms of technology and regulations, we have been operating this room for years in the same way as our other room, with which we have 25 years of experience. Very uncomplicated and safe."

Dipl.-Ing. (FH) Marko Pilz

Production Manager

mecora GmbH, Aachen

Please call us on +49-163-2518059 or write to us at

Contact us

Discuss your project idea with us

sphairlab GmbH

Merzbrück 212

D-52146 Würselen

Deutschland

Contact person

Max Lindemann

Managing Director

Fon: +49-163-2518059

Mail: info_at_sphairlab.com